Product information

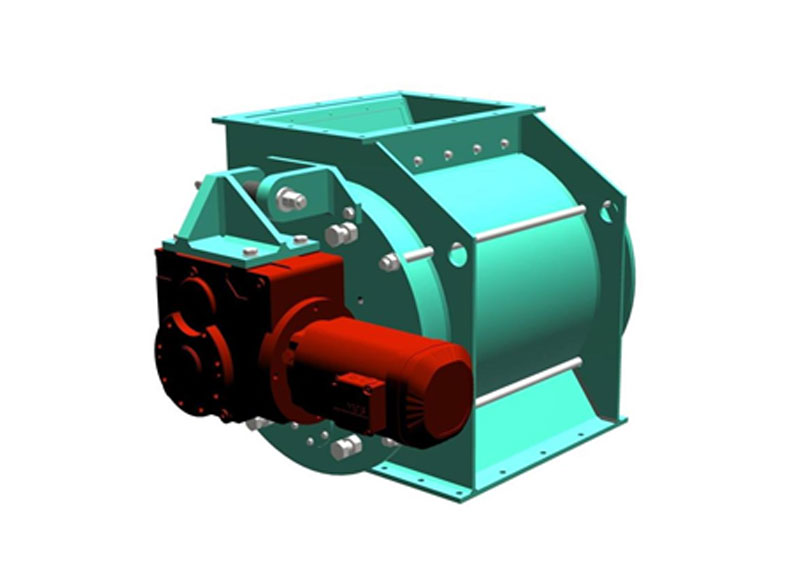

Noxor cell feeders are mainly used for slugging solid fuels such as coal, chips, forest waste and peat. They are tasked with blocking against eg. combustion or gasification processes. The cell feeders have been developed in our own plants and special consideration has been given to the properties of the transporting material. The product range also includes cell feeders for lime and ash.

Technical information

Rotary Cleanup

Noxor carbon feeders have rotor cleaning that allows trouble-free transportation of damp coal. The cleaning takes place when the rubber bottom of the rotor cells is activated with compressed air impulses. This cleaning system has few wear parts and long service life.

Cutting Edges

All cell feeders for fuel lock have rotor blades with replaceable cutting knives of wear-resistant steel and inclined inlet edge. This design is necessary to cope with fuel chips, forest waste and peat that often contain knitting needles and roots. Some feeders have an extra strong design with a rotor dimensioned for jamming e.g. scrap. This type of cell feeder has interchangeable cutting blades in both rotor edges and inlets.

Pressure-tight cell feeders

For particularly demanding installations where extra high pressure density is required, Noxor has developed cell feeders with rotor cleaning, self-compensating rotor blades and spring-loaded axial seals. This design provides a dense feeder for long periods without the need for stoppages for adjustments.

Product range

In order to be able to choose the right type of cell feeder for each operating case, we have divided the cell feeders into the following main groups:

Group 1: Cell feeders for coal or coal and other solid fuels in combination. This type of cell feeder has rotor cleaning that prevents backing of damp material and cutting knives on the rotor wings. The inlet opening is inclined and is available with or without replaceable cutting knife.

Group 2: Cell feeders for biofuels such as wood chips, forest waste and peat. The rotor in this cell type feeder has stainless steel bowls, edge cutting knives and inlet opening with replaceable cutting knife. It should not be used for carbon transport as it lacks rotor cleaning.