Information

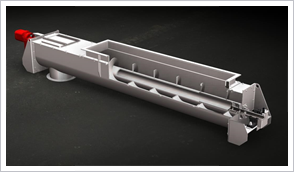

Screw troughs are available in two standard versions: the U-shaped trough and the pipe trough. The pipe trough is generally used for fed screws but can also be used for transporting screws for easy-to-handle materials for which accessibility is not as important. Each type of screw is available in eight standard sizes and can be fitted with standard inlet and outlet adapters or according to customer requirements. Troughs can be black or stainless steel.

The screw end plates, which are identical for U-shaped troughs and for pipe troughs, have standalone steel bearing housings and packing seals at the shaft bushings. This type of bearing gives a long service life, allows heat expansion of the screw shaft and prevents the transporting material from coming into contact with the bearings.

Cleaning hatches in which part of the trough bottom can be opened are attached with hinges with link screw fasteners, allowing quick opening and re-adjustment to ensure the best possible seal against the trough. Inspection hatches attached with hinges that can be re-adjusted comply with stringent sealing requirements.

An inductive speed sensor is provided as standard for all screws. The speed sensor is positioned securely in the supporting end plate.

Screws with U-shaped troughs are fitted with easily removable, mould-curved lids in 1.5 m sections attached with clamping bush caps, making dismantling and assembly much easier during servicing and inspection.

Shafts are either solid-shafts or tube-shafts depending on the length of the screw. All types of shaft undergo centre turning to avoid eccentricity. The threads are cut from sheet metal, welded to the assembly, pulled out to the correct position and welded to the shaft. This method gives full thread thickness at the thread edge, where the wear is greatest. The threads are always adapted to the transported material and are available in several material grades, including S235JRG2, Hardox 400, EN 1.4301 and EN 1.4436. A variety of threading designs and also hard coating of the thread edge are possible.

The screw conveyors are fitted as standard with drive units comprising:

direct-coupled electric motor, shaft-mounted gearbox and V-belt transmission with protective cover. Other types of drives, e.g. shaft-mounted gearbox motor, gear transmission motor with chain transmission or speed variators, are also possible.